Cylinder & Bundle Markings – Quality & Service – Messer - Specialty Gases

Breadcrumb

INFORMATION ON PRESSURIZED GAS CONTAINERS

INFORMATION ON PRESSURIZED GAS CONTAINERS

Technical labeling of gas cylinders

Regulations and safety standards

Regulations and safety standards

Regulations and safety standards

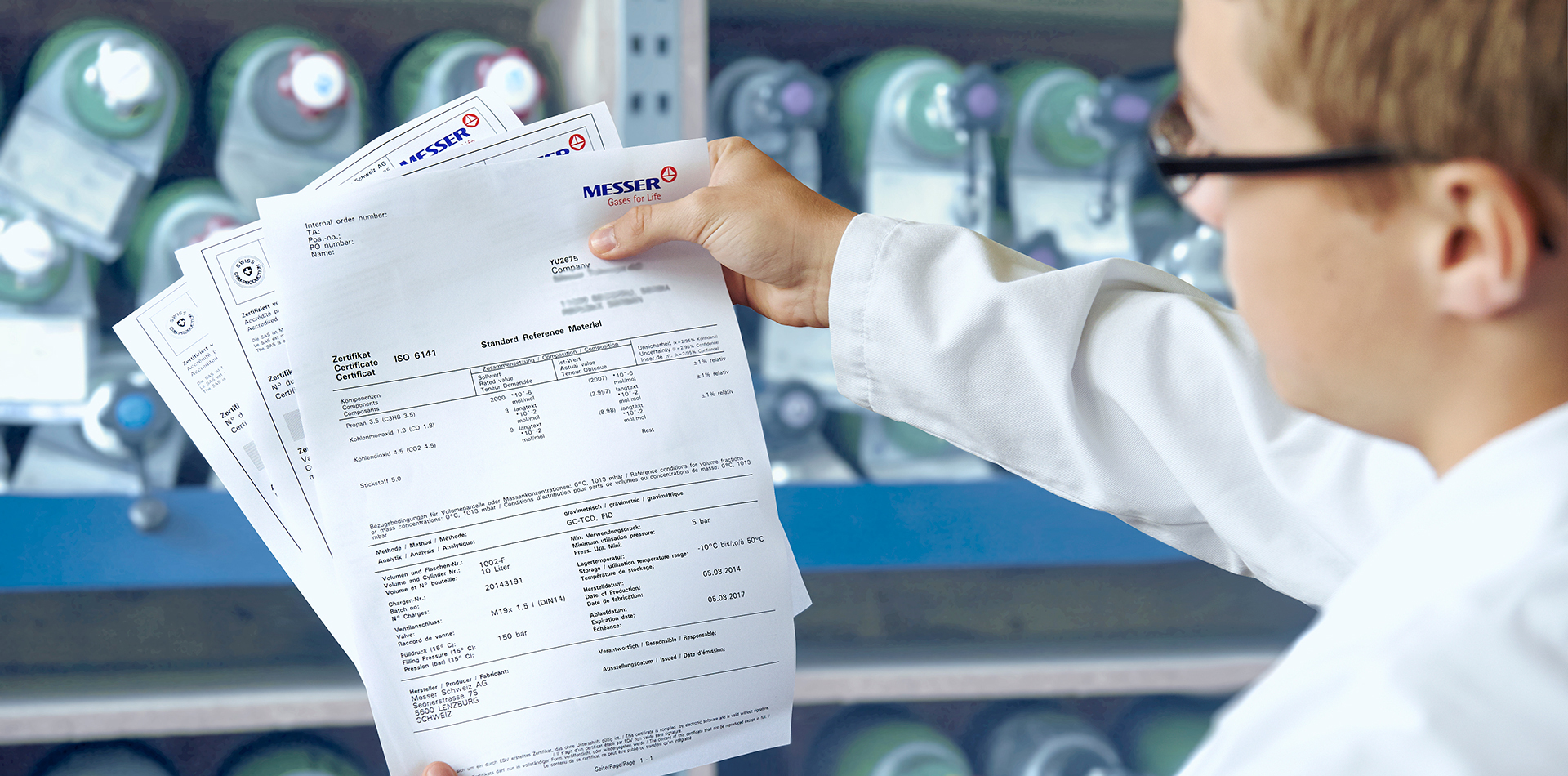

The labeling of gas cylinders is an essential part of safety and risk management reports when handling pressurized gas containers. Each gas cylinder is identifiable by a permanent embossing on the cylinder shoulder, which contains important technical and safety-related data. This embossing includes, among other things, the gas cylinder number, information on approval for specific gases, inspection intervals, material markings, and the cylinder owner.

Stamping and labeling of gas cylinders

It is crucial to understand that the stamping on the shoulder of the gas cylinder does not contain any information about the amount of gas filled. This information is provided in full by the label on the gas cylinder, which, in addition to the stamping, contains precise identification of the gas, its quantity, and specific safety data.

The labeling of gas cylinders follows clearly defined international standards, in particular EN 1089-3, which standardizes the color coding of gas cylinders within Europe. These color codes are used for quick and precise identification of the gas content and at the same time provide important information about the risk potential of the gas.

Color coding according to EN 1089-3: standardized labeling of gas cylinders

The labeling of gas cylinders in the form of color coding is based on four main risk categories:

Nested Applications

Inert gases – shoulder color: bright green

Gases with a low risk of reaction

Shoulder Color: Bright Green

Inert Gases - Noble Gases

Examples:

- Krypton

- Xenon

- Neon

Inert Gases - Food Industry

Examples:

- Banana & Fruit Ripening Gases

- Gourmet Gases

Flammable gases – shoulder color: red

Gases that are highly flammable

Shoulder Color: Red

Flammable Gases

Examples:

- Hydrogen

- Ethane

- Methane

- Propane

Flammable Gas Mixtures

Examples:

- Forming Gases

- Mixtures of Argon with Hydrogen

Nested Applications

Oxidizing gases – shoulder color: light blue

Gases that support the combustion process

Cylinder Shoulder: Light Blue

Toxic or corrosive gases – shoulder color: yellow

Gases that can be harmful to health or destructive

Cylinder Shoulder: Yellow

Toxic and/or Corrosive Gases

Examples:

- Ammonia

- Sulphur dioxide

- Chlorine

- Nitric oxide

- Carbon monoxide

Special Color Codings - Related Products

Brown - Helium

Uniform colors for the labeling of gas cylinders help to identify these categories quickly:

Brown for helium

Argon - Shoulder Color: Green

Dark Green for argon

Cylinders - Nitrogen - Cylinder

Black for nitrogen

Nested Applications

Cylinders - Oxygen - Cylinder

White for oxygen

Cylinders - CO2 - Cylinder

Grey for carbon dioxide

High purity gases

PURE GASES

From Argon to Xenon - Messer's extensive product portfolio of high purity gases

Technical requirements

This standardized labeling of gas cylinders not only improves safety in the storage and handling of gases, but also facilitates compliance with legal regulations and safety standards.

Technical requirements for gas cylinders and their labeling

The labeling of gas cylinders goes beyond visual color coding. Each gas cylinder must meet the technical requirements defined in the relevant standards and regulations, such as the maximum permissible filling quantity, the operating pressure (often 200 or 300 bar), and the material of the cylinder (e.g., steel or aluminum). The precise labeling of gas cylinders also includes technical data such as:

- Contents in cubic meters (m³)

- Outer diameter

- Length of the cylinder

- Empty weight of the cylinder

For special applications there are also high requirements for gas purity, especially for high-purity gases such as helium, argon, and nitrogen, which are supplied in specific cylinder types (steel or aluminum gas cylinders) and various sizes.

Conclusion: importance of gas cylinder labeling for safety and efficiency

The labeling of gas cylinders is an integral part of safety regulations for handling pressurized gas containers. It enables quick and accurate identification of gas types and helps to minimize risks during handling and storage. Precise labeling of gas cylinders, including color and embossed labeling, is, therefore, essential to ensure efficiency and safety throughout the entire life cycle of a gas cylinder.

Packaging Sizes - Table

|

|

[m3] |

[mm] |

[mm] |

[kg] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bundles |

Gas Content [m3] |

Dimensions (L / W / H) [mm] |

Empty Weight [kg] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Related Products

High purity gases

PURE GASES

From Argon to Xenon - Messer's extensive product portfolio of high purity gases

Calibration gases

Download Files Portlet

Specialty gase page

SPECIALTY GASES

Do you have high standards? We do, too. Specialty gases from Messer